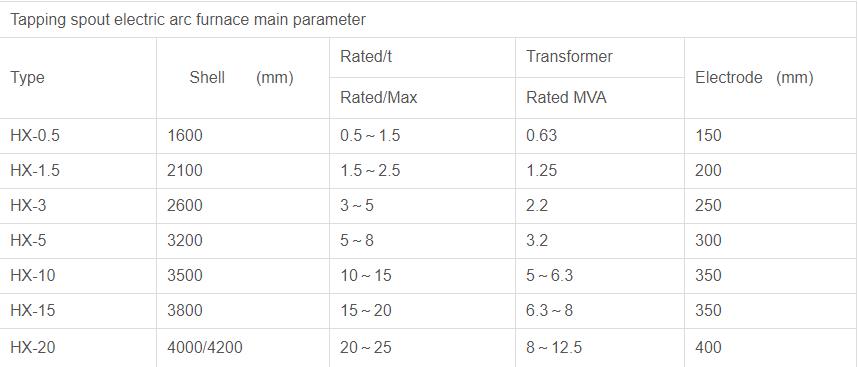

Tapping Spout EAF

Night vision function:

Goods gross weight:

Shelf time:

Product description:

(1) Foundry plant and small size steel plant widely use;

(2) Compared with EBT, melting down, oxidation and reduction inone furnace;

(3)Limited investment & area occpuation & high income;

(4)High quality molten steel,P,S & C can be controlled to meet thedemand;

(5) Samller size & capacity easier operation, convenientmaintenance;

(6)Highly flexible for both steelmaking and casting;

Tapping Spout EAF(Electric Arc Furnace)

Equipment composition:.titing mechanism, furnace shell assembly, water-cooled roof, roof liting and swing device,electrode lifting device, high current system, cooling water system, hydraulic system, electrode extension station, electricfurnace transformer, high voltage cabinet, low voltage electronic control system and so on.

Furnace features: The overall structure of the furnace adopts an elevated structure and a connected structure. Thefurnace roof is swung off & charging from top, the copper-steel composite conductive cross arm supply power , and theshort spout for discharge slag, while long spout for tapping molten steel.

The electric arc furnace roof swung off and the electrode is arc-started.The whole process of smelting is about 90-250minutes, depending on the size of the transformer, oxygen decarburization and phosphorus removal can be achieved inthe melting down process, after the molten steel reach the temperature and composition required, liquid steel tapping outfrom the tapping spout with temperature around 1600-1700°C;