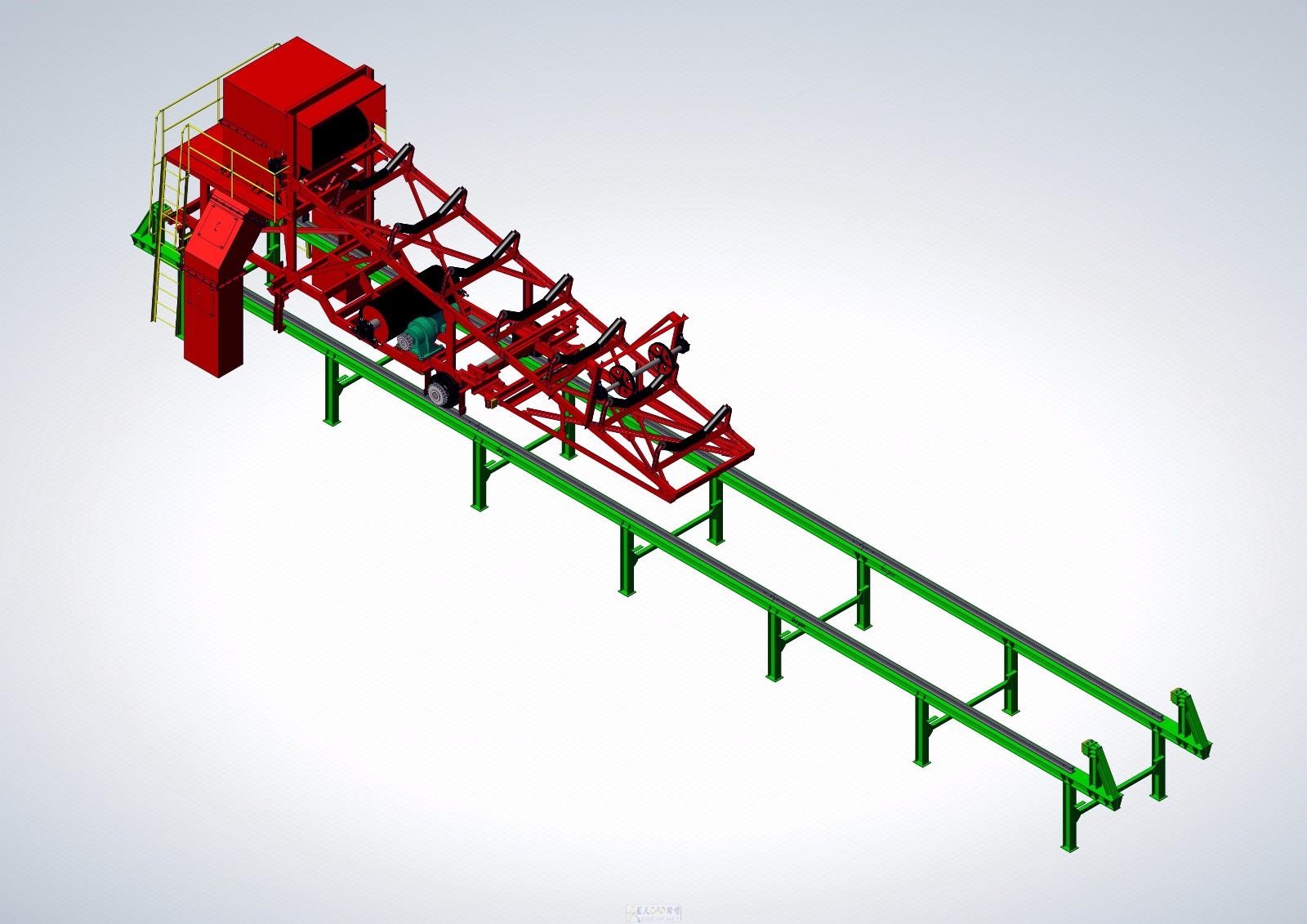

Railway Belt Conveyor Tripper Car Chute Tripper Conveyor Materials Handling Tripper Car

Product Description

Belt conveyor with railway tripper car self propelled reversing cross belt tripper

| A | Frame Tripper Car Conveyor 卸料小车输送机 |

| 1 | Frame & Support Tripper Conveyor 框架 & 支架卸料输送机 |

| Frame UNP 150x75x6,5 & L75X75X6 框架UNP150x75x6,5 & 长75X75X6 | |

| Plate t 8 mm 板厚8mm | |

| 2 | Frame Galery Tripper Car 框架式卸料车 |

| L120x120x12, Gusset Plate t10 mm 尺寸长120x120x12, 角撑板厚10 mm | |

| L 75x75x6 & L 65x65x6 长 75x75x6 & 长 65x65x6 | |

| UNP 125x65x6x5 尺寸UNP125x65x6x5 | |

| 3 | Maintenance Deck, Tripper Conveyor 维修平台,卸料输送机 |

| Walkway, Expanded Metal & L 75x75x6 走道,金属板和长 75x75x6 | |

| Hand rail , L 50x5 & Pipe dia 11/4" & pipe dia 1" 扶手,L 50x5 & 管道直径11/4" 和管道直径1” | |

| 4 | Support Tripper Car point3 支撑卸料小车点3 |

| WF 250x125x7847 & Gusset Plate WF250x125x7847 & 角撑板 | |

| UNP 150x75x8600 尺寸UNP150X75X8600 | |

| L 75x75x6 长75X75X6 | |

| WF 200X100x5,5x8 WF 200X100x5,5x8 | |

| 5 | Support Tripper Car point2 支撑卸料小车点2 |

| WF 250x125x6x9 & Gusset Plate WF 250x125x6x9 & 角撑板 | |

| UNP 150x75x6,5 UNP 150x75x6,5 | |

| L 75x75x6 长 L 75x75x6 | |

| WF 200x100x6x9 WF 200x100x6x9 |

Introduction:

Our production of the unloading tripper car is based on the advanced technology and experience at home and abroad

on the basis of the design, is the original TD75 belt conveyor heavy, light unloading truck series ideal upgrade

dust control unique. This series of unloading tripper car can be widely used in metallurgy,mining, thermal power,

building materials, coal, fire and other industries.

This series of discharge tripper car for conveyor since the success of the study, due to the use of good performance in the

South Steel, Guizhou Goupitan power station, Ma On Shan, on the steel and other industries have been widely

used by users praise.

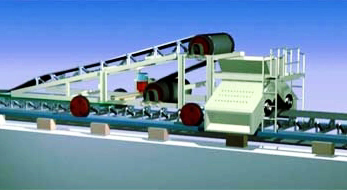

For applications where more than one conveyor discharge position is required, we offers several approaches and options to meet the demands of the project, among them, belt trippers, belt plows/belt diverters, and reversing shuttle conveyors. Whether you need a reversing belt with discharges at both ends, filling multiple bins along the length of the conveyor, or you need to create a long continuous pile such as in filling a bulk storage building, we have your bulk material handling needs covered.

BELT TRIPPERS

A belt tripper is used to "trip" the material off the conveyor at specified locations between the terminal pulleys. A belt tripper can either be in a fixed position, or travel continuously at a constant speed for layered stacking.

A belt tripper consists of a structure with two pulley assemblies. As the belt passes over the upper pulley, the material is discharged from the belt into a collection chute. The material is then diverted to one side or both sides of the belt for discharge, or back onto the belt if the desired discharge position is at the end of the conveyor. Several powered drive options and chute configurations are available.

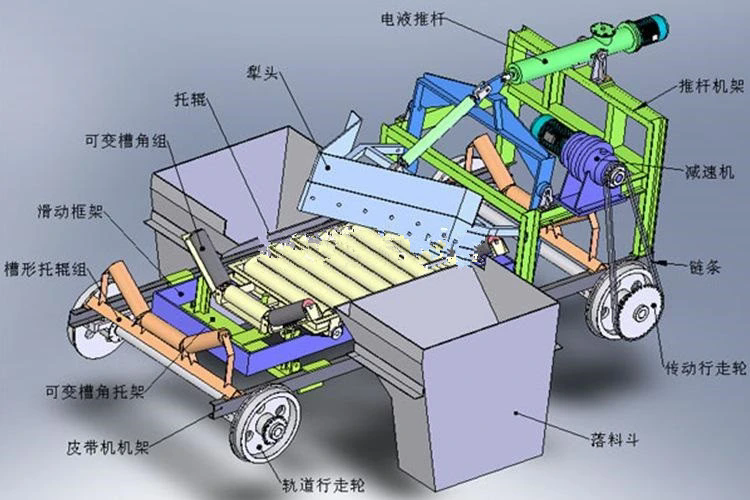

FEATURES

- Four wheel drive

- Heavy-duty Construction

- Custom Design:our belt trippers are designed around your unique requirements and how the material flow should be re-directed. Common options include one, two, or three way discharge chutes with diverter and/or auxillary feeders (screw feeder, reversible belt feeder, etc.).

- Engineered Pulley Loop: The conveyor belting travels through a set of pulleys which create the material "trip," or discharge point and then redirects the belt back on to the idlers. This "pulley loop" is designed so the conveyor belting will experience a very limited amount of stress, eliminating the opportunity for premature wear and stretching.

- Direct Drive: our belt trippers are equipped with direct mounted motor and gear reducers that are separate from the main conveyor drive components. This allows for the tripper travel to be controlled from either a remote or local location.

A - Discharge Pulley

B - Return Bend Pulley

C - Cable Reel

D - Rail and Rail Support Beam

E - Tripper Wheels

F - Direct Drive Motors

G - Tripper Wheels

H - Diverter Chutes

I - Discharge Hood