PRODUCT DETAIL

1. Different capacity up to 200t;

2.Different structure, and discharge control;3.Mature deign, know-how technology;

4.Different structure, different design with highly customized;5.Punctual delivery, high end quality, and attentive service aftersale;

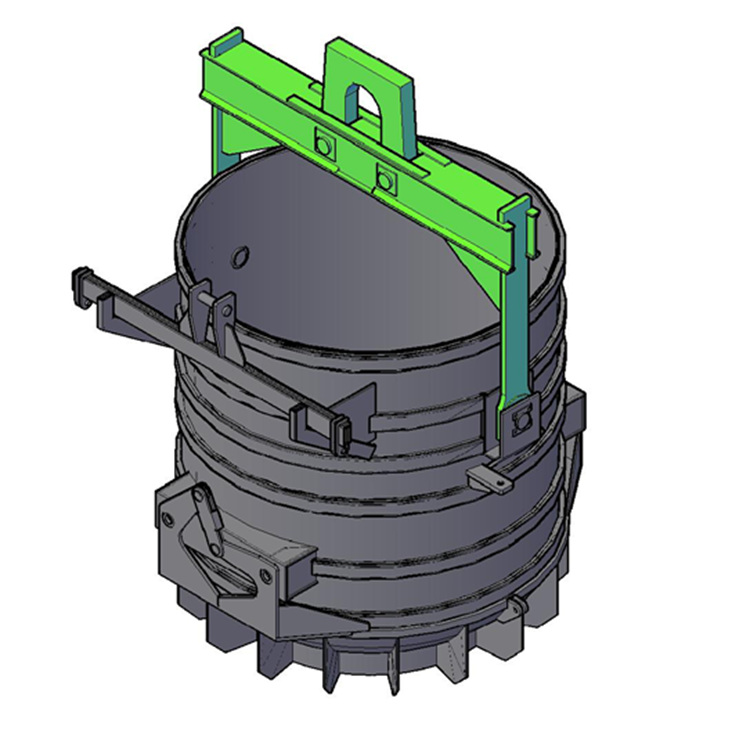

The scrap bucket bottom usually is a clam shell design-i.e. the bucket opens up by retracting two segments on thebottom of the bucket. Some large-tonnage bottom-opening scrap baskets do not match the ferroalloy melting furnace incaliber, resulting in more material perpendicular to the opening direction and uneven fabric. Uneven fabric sometimescauses scrap to stick to the lining, affecting the life of the lining; sometimes it will cause the scrap to fall on the under-railrail, affecting the normal operation of the under-vehicle, increasing the workload of the operator, The scrap steel is placedat the tapping port and the tapping port, away from the electrode, which affects the heating speed of the scrap steel. Theblockage of the furnace mouth also affects the oxygen blowing operation of the operator and observes the molten steel inthe furnace. In view of the above shortcomings of the large tonnage bottom-opening type feeding basket, it is necessaryto improve it to ensure smooth production.

NEED HELP

LEAVE A MESSAGE

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Copyright © VILLE INDUSTRY CO.,LTD.