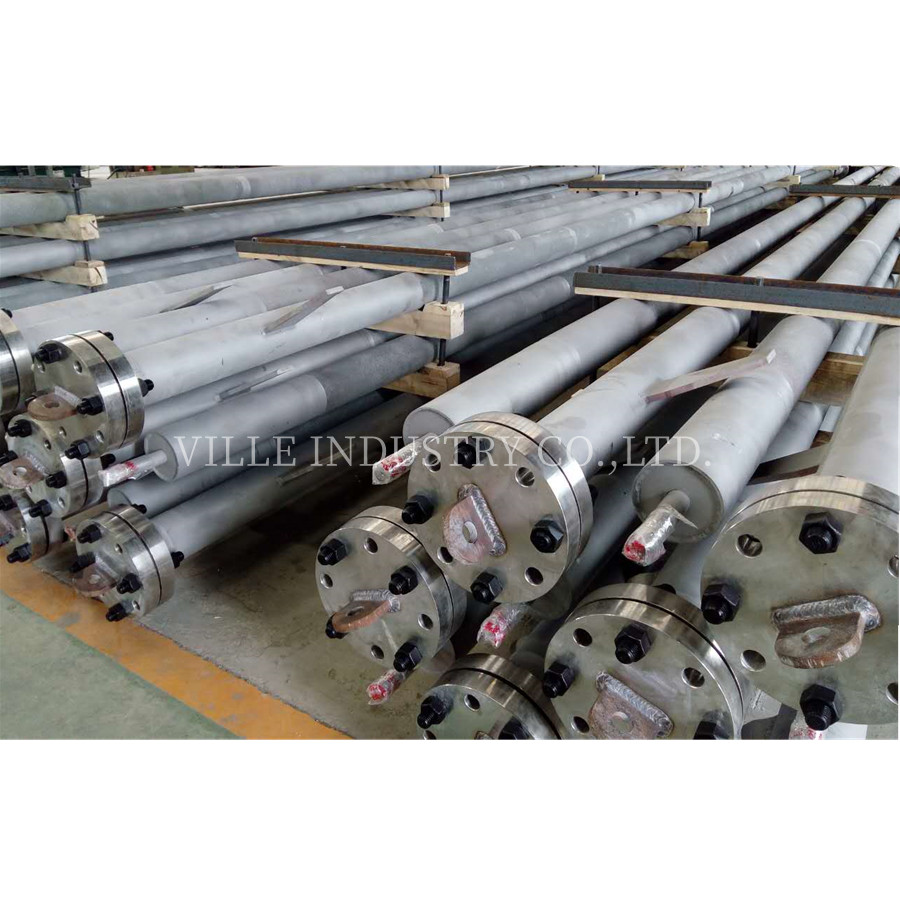

Centrifugally cast Reformer Furnace Tube reformer pipe

Centrifugally cast Reformer Furnace Tube reformer pipe

Reformer Tube Assemblies, acc to drawing in total consisting of:

Qty/Tube Description Material

Top tube, ID200 x MSW 11.2xLg 4695 mm

Bottom Tube, ID 200x MSW 11.2xLg 4695 mm

Top Welding Neck Flange, Lg 160 mm

Lug.G4 Pins welded to the bottom tube

Alignment Sleeve. 80 mm

Technical Description; Reformer Tubes:

Centrifugally cast, outside a cast, inside machined to max.3.2 Ra

Specifications:

1. Configuration and Arrangement

the tube shall consist of a top part (flange),a tube upper section and a tube-lower

section, drawing (I):The tube assemblies are vertically suspended from the top

outside the reformer. Bottom flange is arranged outside the reformer as well.

2. Operating Condition

Gas inlet temperature 400℃

Gas outlet temperature 930℃

Gas inlet pressure 2 bar

Max. tube skin temperature :

Upper section 1070℃

Lower section 1050℃

Reformer roof temperature : 1130℃

3. Materials

|

|

|

|

|

|

|

Top (Flange) HP-Nb 160mm |

Upper Section HV 4695mm |

Lower Section HP-Nb 4695mm |

|

C% |

0.35-0.45 |

0.35-0.55 |

0.35-0.45 |

|

Ni% |

34-36 |

47-50 |

34-36 |

|

Cr% |

24-26 |

27-30 |

24-26 |

|

W% |

|

|

|

|

Nb% |

1.2-1.8 |

- |

1.2-1.8 |

|

Si% |

Max.1.5 |

0.5-1.5 |

Max.1.5 |

|

Mn% |

1.0-2.0 |

1.0-1.5 |

1.0-2.0 |

|

P% |

Max.0.03 |

Max.0.03 |

Max.0.03 |

|

S% |

Max.0.03 |

Max.0.03 |

Max.0.03 |

|

Mo% |

Max.0.5 |

Max.0.5 |

Max.0.5 |

|

AL% |

Max.0.05 |

Max.0.05 |

Max.0.05 |

|

Ti% |

Max.0.15 |

Max.0.15 |

Max.0.15 |

|

Cu% |

Max.0.15 |

Max.0.15 |

Max.0.15 |

|

Sn% |

Max.0.01 |

Max.0.01 |

Max.0.01 |

|

Pb% |

Max.0.005 |

Max.0.005 |

Max.0.005 |

|

Mechanical Properties Yield strength tensile strength elongation |

245 N/mm² 450-650N/mm² 8% |

440 N/mm² 4% |

245 N/mm² 450-650N/mm² 8% |